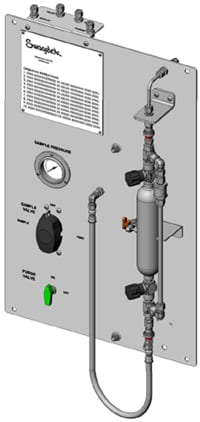

Grab Sample Panels

We, at Swagelok, understand your need for safe, reliable, compatible and customizable grab sample systems. Our latest offerings provide you with best practice designs, smart part numbers, BOM generator and configurable CAD files along with assembly instructions. This is all backed by Swagelok's Limited Lifetime Warranty and our industry-leading training.

Grab Sample Module (GSM) Design Features

- Geared valves offer fool-proof operation

- Swagelok's geared 3-way valve is used to always provide a fresh sample from process, in the fashion of a fast loop. Operators can actuate both 3-way valves with one throw, causing no liquid hammer

-

Standard design offers consistent installation throughout your facilities - Purge option enhances safety of operator in toxic applications - purges all lines, including quick connects

- Introducing purge fluid into process line is impossible

- Versatile mounting options:

- 2" pipe stand (Clamps included)

- Mounting holes for 1-5/8" Unistrut® or 45mm frame members

- 304 stainless steel construction (non-wetted materials)

- GSM design platform offers limitless customization options

- Liquid cylinders fill from bottom so trapped gas can escape

- Gas cylinders fill from top so condensate is flushed from cylinder

- Glass bottle sampling

- The needles used on the Swagelok GSM are "non-coring." This means the needles will not core out a hole in the glass bottle rubber cap. They are stronger and less likely to bend.

to learn more

Tech Tips

Avoiding Classic Liquid and Gas Sampling Mistakes

Whether you're working with a gas or a liquid sample, common sampling system mistakes often occur during initial design. Learn how to avoid classic sampling mistakes and get better gas and liquid samples every time with design tips from Swagelok.

How to Select the Right Sample Preconditioning Module

When selecting a sample preconditioning module for your sampling system, there are several factors to keep in mind to ensure sample accuracy & plant safety. Swagelok Product Manager Randy Rieken gives tips on how to choose a proper module.